The decision to use shielding materials for shielding against high-frequency electromagnetic electrosmogElectrosmog is a colloquial term for all emissions from electric, magnetic, and electromagnetic fields. More RF and low-frequency electric fields NF is a clear YES to supporting one’s own health. These materials, however, are a sophisticated shielding technology which has certain characteristics that must be taken into account. On this FAQ page we present these collected so that the project SHIELD works completely and the goal is achieved.

Depending on the application, select the appropriate tab for details on the shielding material.

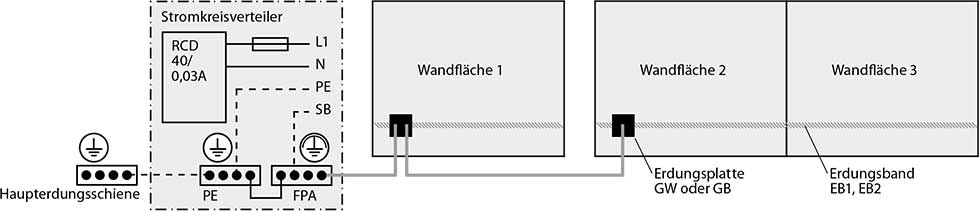

Grounding is one of the most common issues when shielding electric fields. These must always be carried out by the electrician.

Large-area shields with shielding materials are not electrical equipment but “foreign conductive parts” according to IEV 826-03-03 or IEV 195-06-11 and thus a new method of DIN VDE 0100-100: 2009-06. By connecting to the equipotential bonding they are part of the electrical system, therefore, the recognized rules of technology must be observed.

According to the latest state of the art, a distinction is made between protection and functional potential equalization (FPA).

The most frequently asked questions about shielding paints are paint selection, processing, substrate and ecology / environmental compatibility.

The adhesive tensile strength serves as a parameter for the adhesion of layers to a substrate. Our shielding paint are applicable inside, outside, under plaster and much more. And after the shielding paint a variety of top coats are used. The common question then is: which type of coating adheres to which shielding paint?

The tensile strength according to ASTM D4541, ISO 4624, DIN EN 13813 is determined under defined conditions (measuring surface, take-off speed, etc.). A tensile testing machine pulls the glued stamp down evenly until it breaks off. The adhesive tensile strength can never be higher than the intrinsic strength of the individual components, in the composite is always the weakest link prevail.

|

|

|

|

Since we sell our shielding paint worldwide, it is not possible for us to name and test all variants of topcoats. It is therefore important to note that the application and processing is beyond our control. The following table should be an aid for information, no liability can be derived from the following table. In the case of uncertainty on site, we strongly recommend carrying out a test coating on a test surface.

Below is a table which gives advice on which types of coatings (paints, plasters, fillers) should always be compatible with which shielding paint:

60.3563

| NSF34 | HSF54 | HSF64 | PRO54 | DRY69 | |

| Dispersion (organic) from acryl, styrol, vinylacetat, polyurethan, epoxid | + | + | + | + | + |

| Silicate emulsion ((in)organic) from sodium silicate and plastic | + | + | + | + | + |

| Sol-silicate (inorganic) from sodium silicate and silica sol | o | o | + | + | o |

| Pure silicate (inorganic) from sodium silicate | – | – | – | o | – |

| Silicon resin (organic) from organopolysiloxanes | + | + | + | + | + |

| Natural resin (organic) | – | – | o | o | o |

| Casein (organic) | – | – | – | – | – |

| Cellulose, glue (organic) | – | – | – | – | – |

| Lime, chalk (inorganic) | – | – | – | o | – |

| Pit lime (inorganic) | – | – | – | – | – |

| Cement (inorganic) | – | – | – | – | – |

| Loam (inorganic) | – | – | – | o | – |

| Clay (inorganic) | – | – | – | o | – |

Our shielding paint are very flexible and universally applicable. An advantage compared to wallpaper, fleeces or fabrics is the simple color typical processing. Every painter can professionally process our shielding paints with only one painter’s roller without special expertise or training. Even applying an airless spray with appropriate spray is easily possible.

Many metal shielding products are not corrosion resistant. Our shielding paints contain no metals but a mixture of carbons. These are chemically stable and permanently corrosion resistant, even in humid environments.

YShield has VOC (Volatile Organic Compound) and PAH (Polycyclic Aromatic Hydrocarbons) tested by TÜV SÜD.

Every aqueous paint must be preserved. Often disputed are isothiazolinone compounds, which, however, refers only to CIT and this is not included in our colors. We refuse a preservation as in eco-colors with BIT / silver, because we do not want to use nanosilver.

Our conservation with MIT / BIT has a very low allergenic potential, which many MCS customers confirm. And if a shielding paint is absolutely necessary, which is 100% free of preservatives, we have a wonderful alternative with our HSF74 shielding paint.

Due to the color-typical full-surface shielding without holes, our shielding paint offer a nearly linear shielding attenuation up to very high frequencyFrequency is the number of occurrences of a repeating event per unit of time. It is a physical measurement that is important for describing periodic processes, such as vibrations. More ranges, without preferential polarization. This would be tested up to 18 GHz and thus our shielding paint are very future-proof.

Our shielding paints do not contain any solvents, plasticisers or other problematic ingredients. All ingredients were selected independently of price, solely for their safety and high quality.

Information and products for the necessary grounding, we have linked in the shop category grounding. See also the tab “Electrical“.

Detailed processing instructions can be found directly on the shielding paint in the shop and the linked technical data sheets on the corresponding product pages.

The most common questions about shielding fabrics are the choice of fabric and gentle cleaning of the shielding fabric.

Shielding fabrics lose screen attenuation during washing and when moving. Since there are many false rumors circulating, we are releasing YShield’s ninth washing test of August 2016.

YShield has washed all the substances known on the market 50 times at 30 ° C. It was washed in parallel on 2 washing machines (BOSCH and SAMSUNG) and the values averaged. The detergent used was a detergent suitable for silver substances.

An interesting feature of the measurement procedure according to ASTM D4935-10 is that it measures radially, ie in all polarization directions, this is the closest thing to reality! With TEM measuring cells it is possible to measure from 30 MHz to 18 GHz in one pass.

Explanation of the following screen attenuation graph: The orange bar is the original screen attenuation without washing. The legend to the left of the scale represents the screen attenuation in dB at 1 GHz. Each additional bar represents “after 10 washes”.

All our shielding fabrics provide a good to very good result at 30 ° C wash temperature. This is because over the years we have removed all unstable materials from the range. Many shielding fabrics of the competition (not in the diagram) the measured values speak a very clear language. We had fabrics at hand which fell from 30 dB to 7 dB after only 2-3 washes. If higher washing temperatures are necessary, this should be requested from us.

Fabrics with silver threads change color over time! Sometimes substances are already discolored when we get them from the manufacturer! This process is absolutely normal for silver. Reasons for this are sunlight, heat from the radiator, splashes of water, sweat, etc.. Discolored areas do not affect the shielding effect (screen damping) and are not a quality defect!

If you can not accept a discoloration, you will find in the shop various substances that can not discolor with it automatically associated much lower shielding attenuation. Here are a few examples of how such discoloration (worst case) might look like:

Fabrics with unprotected silver threads (Silver-Tulle, Silver-Elastic, Silver-Silk) have a limited shelf life. The lifetime basically depends on the frequency of the movement.

More and more textiles for sports, atopic dermatitis, etc. contain nanosilver. Due to their size, these tiny nanosilver particles can penetrate the skin into any body cell and cause massive damage. The Federal Environment Agency warns of these serious knowledge gaps.

However, thick layers of “metallic silver” are harmless to humans and the environment. All our silver yarns as well as our full silvered textiles are covered with 99% “metallic silver”. Even if heavy particles (such as clothing or bedding) are released over time, they are far too large to penetrate the skin through the skin!

Very popular are our custom-made curtains, which we sew very cheaply for end customers. You pay only the running meters of the corresponding material and proportionally the necessary sewing! Per curtain we need and charge 15 cm hem surcharge.

Our shielding fabrics have different widths from 130 cm to 260 cm. You can sew the fabric width or the fabric length either as height or width of the curtain. In the width of a curtain about 8 cm are lost by sewing. At height, about 15 cm are lost for the curtain and weighting band. How high and how wide a single curtain can be depends on the fabric width!

Example if you want to cover an area of 400 cm width and 230 cm height:

If you need help with planning we will be happy to help!

Some fabrics (e.g., Silver Twin, Steel Twin) have a lighter front and a darker back with the metal threads. This makes these fabrics wonderful for opaque curtains. The bright side towards the room is our standard. If you want the darker metal thread side towards the room, please let us know.

We understand all dimensions you call us, as finished sewn final dimensions (including curtain tape, tunnel, sewn-in sides, etc.). For drapery you have to calculate 25 – 50% oversize in width! For most fabrics we achieve a dimensional accuracy of +/- 2 cm. Elastic fabrics (such as Silver-Tulle, Perspective) are difficult to sew, the dimensional accuracy can be up to +/- 5 cm!

In general, the shielding is more important than a perfect look!

In general, it’s quite difficult on the internet to judge a supplier’s integrity based on a website. A hypothetical example: a supplier has a professionally designed website, as his main profession is e.g. web designer. The shielding paints offered on his website might be mixed on a part-time basis as small entrepreneur.

If YSHIELD had samples of it in their laboratory, it would be immediately determined that all physical and chemical parameters are inadequate, up to and including unfitness for use. Legal labelling obligations would not be fulfilled.

Whoever decides on such a product would not have made a particularly good purchase, since even unsuccessful shielding is associated with costs and effort. Such products not only harm the supplier himself, but the entire building biology industry.

PROnatur24® relies on YSHIELD’s HF technology, HF products and quality for both professional and building biology reasons. We visited YSHIELD in person and took a look at the production facilities ourselves.

YSHIELD has high-end measurement technology up to 40 GHz in its own in-house EMF laboratory for daily development and quality assurance. This is because the shielding effectiveness is the most important criterion for a shielding paint.

Shielding paints are more and more often promoted with a shielding attenuation up to 40 dB (99,99%). When tested in their laboratory they often have only a shielding attenuation of 10dB (90%) – that’s factor 1000 less!

One reason for this might be, that the competitor assumes that his shielding paint shields as well as our shielding paint does, because he thinks there is no difference in the quality of graphite: thus, he uses our indications unaudited. Always ask for a professional measuring done by prestigious experts!

In the past there was yet another reason for that: the client provided an already completely painted sample board to the expert. It was then assumed – without further checks – that the indications concerning material and spreading rate were correct. Frequently the client sent in a sample board that had been secretly painted with several layers and way too thick. With support of PROnatur24®, YSHIELD has revealed this unacceptable situation and have very intense contact to all prestigious experts since that time. That’s why you can trust professional measurements by now.

Sometimes an ‘absorption ratio’ is promoted for shielding paints. YSHIELD has two setups on their premises to measure the absorption capacities of materials: According to IEEE Std 1128-1998 and by 1-port-measurement with a vector network analyser.

There is the general assumption that “metallic” products reflect the pollution, whereas products on “based on carbon” absorb the pollution. YSHIELD has successfully disproved and destroyed this myth about HF absorption.

The lower the electrical resistance, the more will be reflected. The higher the electrical resistance, the more will be absorbed. BUT: a high shielding attenuation (low resistance) conflicts with the needed high resistance for a good absorption.

YSHIELD has measured that shielding paints with a typical shielding attenuation of 40 dB have an absorption of less than 0.01dB at the most. This conflicts with advertising promises of 15% absorption. This value is also quite often only theoretically calculated, with doubtful measured values on the lower end of the frequency range.

Even the new wonder material graphene does not cause an absorption for low resistance shielding paints! After hundreds of material samples, YSHIELD can for sure confirm this fact.

When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Control your personal Cookie Services here.