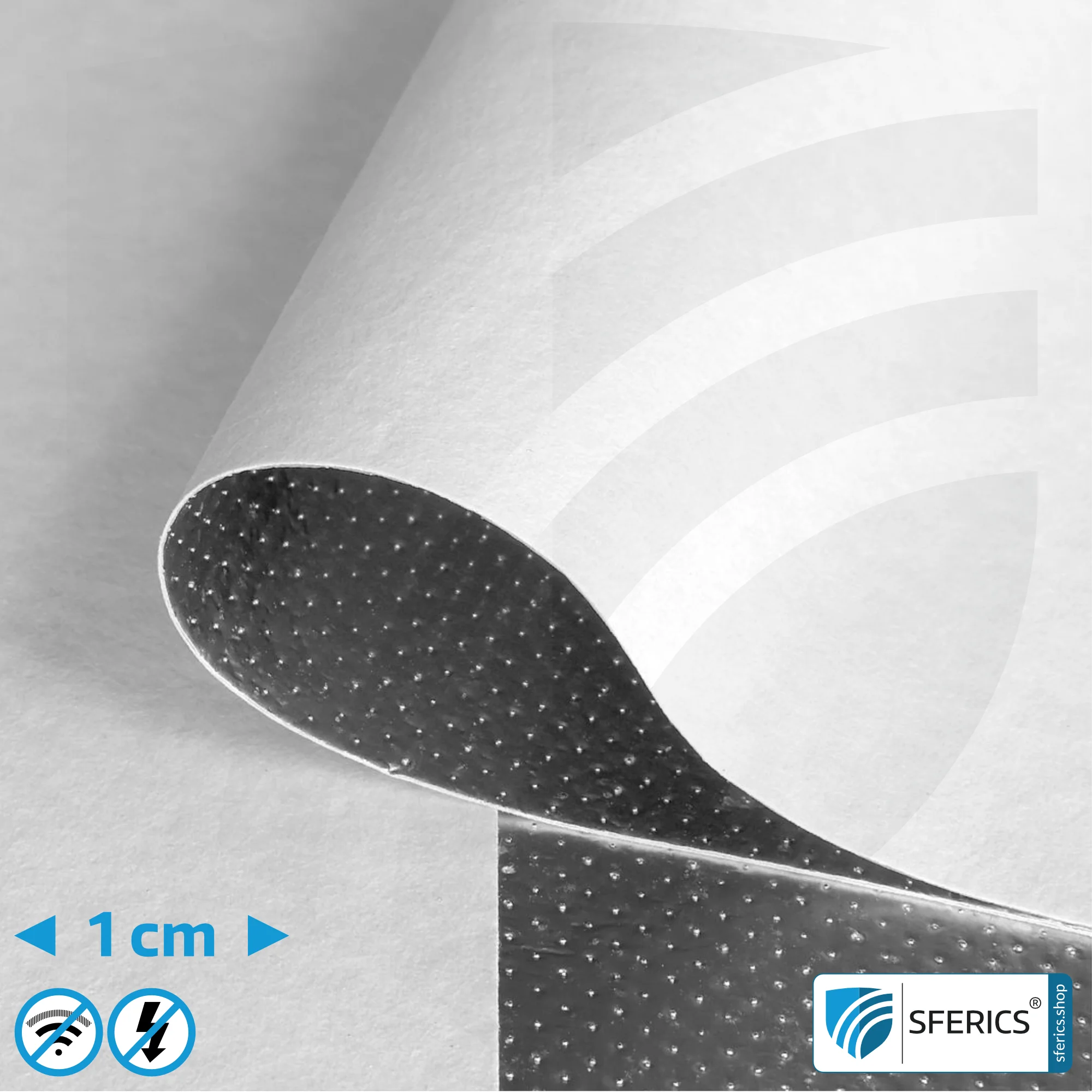

The SAFEBUILD® K150 shielding wallpaper is a paper-based wallpaper laminated on one side with a thin, micro-perforated aluminum foil, offering an extremely high shielding attenuation of up to 100 dB. Designed for versatile indoor use, it is highly breathable and highly permeable to water vapor. Width: 70 cm. Currently undergoing testing by TÜV-SÜD.

Price per Meter (70 x 100 cm)

Quantity = Number of Meters

Our SAFEBUILD® K150 shielding wallpaper is a thin, dimensionally stable wallpaper paper laminated on one side with a thin, micro-perforated aluminum foil, designed specifically for extremely high protection against electromagnetic fields. Thanks to 200.000 tiny holes per square meter, this shielding wallpaper is highly breathable and highly permeable to water vapor, while also providing an extremely high shielding attenuation value of 100 dB. This unique micro-perforation was a central aspect in the development of this innovative shielding technology and does not affect the shielding attenuation, meaning the electromagnetic shielding remains effectively intact.

The SAFEBUILD® K150 shielding wallpaper is not only suitable for high-frequency electromagnetic fields (HF) but also provides excellent shielding for low-frequency alternating electric fields (LF) (grounding).

This powerful shielding wallpaper provides an effective solution for people living in rental apartments. Since permanent shielding installations in rentals often require extensive and costly removal upon moving out, many people currently have no option other than using a canopy. While our canopies are a biophysical breakthrough, their shielding effect is limited to the bed area. With this shielding wallpaper, we are breaking through this limitation, expanding shielding options to the entire room. Upon moving out, the wallpaper simply needs to be removed from walls and ceiling, with minor post-treatment required to restore the original state.

Due to its excellent dimensional and moisture stability during application, the SAFEBUILD® K150 shielding wallpaper can be used universally indoors for any conceivable application.

Only suitable for loose laying if the aluminum layer is protected from mechanical damage.

Grounding the SAFEBUILD® K150 Shielding Wallpaper

This product, with its electrically conductive surface, must be grounded by integration into the functional equipotential bonding (FEB). Suitable components can be found in the Grounding product category. For this product, the aluminum side must be grounded, meaning our GSX grounding tape should be applied to the silver side!

SAFEBUILD® K150 Shielding Wallpaper | Under Review by TÜV-SÜD

This shielding wallpaper is currently undergoing testing by TÜV-SÜD. Based on TM-22 guidelines (version 08-2020), it is being assessed for heavy metals, SVOCs, and emissions. Given the non-toxic and emission-free nature of all raw materials, this test is expected to be successfully passed.

Substrate: Absorbent and chalky substrates must be pre-treated with our primer GK5.

Bonding the aluminum side towards the room: Technically the best solution. All strips can be easily connected afterwards with the GSX earthing tape. Also the best solution with wallpaper replacement primer so that the wallpaper can be removed again if necessary.

Bonding the white side towards the room: Visually the nicer solution that is also easy to rework.

Adhesive: Adhesive for heavy wallpaper on the fleece side. Cellulose adhesive does not adhere to the aluminum side, we recommend our PSA adhesive, which creates a self-adhesive surface. Our aluminum products adhere very well when installed wet and dry.

Butt-jointed or overlapping: The sheets should be glued overlapping to achieve the best shielding result. Glue the overlap with our PSA adhesive. Finally, smooth and sand with a fine spatula. Alternatively, bond as usual, but this will result in minimal losses when shielding very high frequencies.

Contact materials: Due to the aluminum layer, a neutral pH value of pH 4-9 must be ensured for all direct contact materials during processing.

| Country of origin | Germany |

|---|---|

| Brand |

When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Control your personal Cookie Services here.