ecoturbino® | SAME shower pleasure, MORE hygiene, LESS water, LESS costs, much LESS limescale

webdeals is a shop cloud. The networking of modern, specialised webshops with a thematic focus. WEBDEALS » here will be found!

The HSF74 shielding paint is a pure silicate paint WITHOUT PRESERVATIVES and has very high ecological properties. This shielding paint is only recommended for people who are allergic to a preservative. Contrary to the HSF54 shielding paint, the HSF74 is not frost-resistant for shipping and is limited to indoor use only. Due to the risk of frost, shipping between november and february is therefore possible.

Best suited to shielding against radiation caused by mobile phones, DECT, WLAN and mobile internet. Can be grounded to shield against electric alternating fields from the power supply.

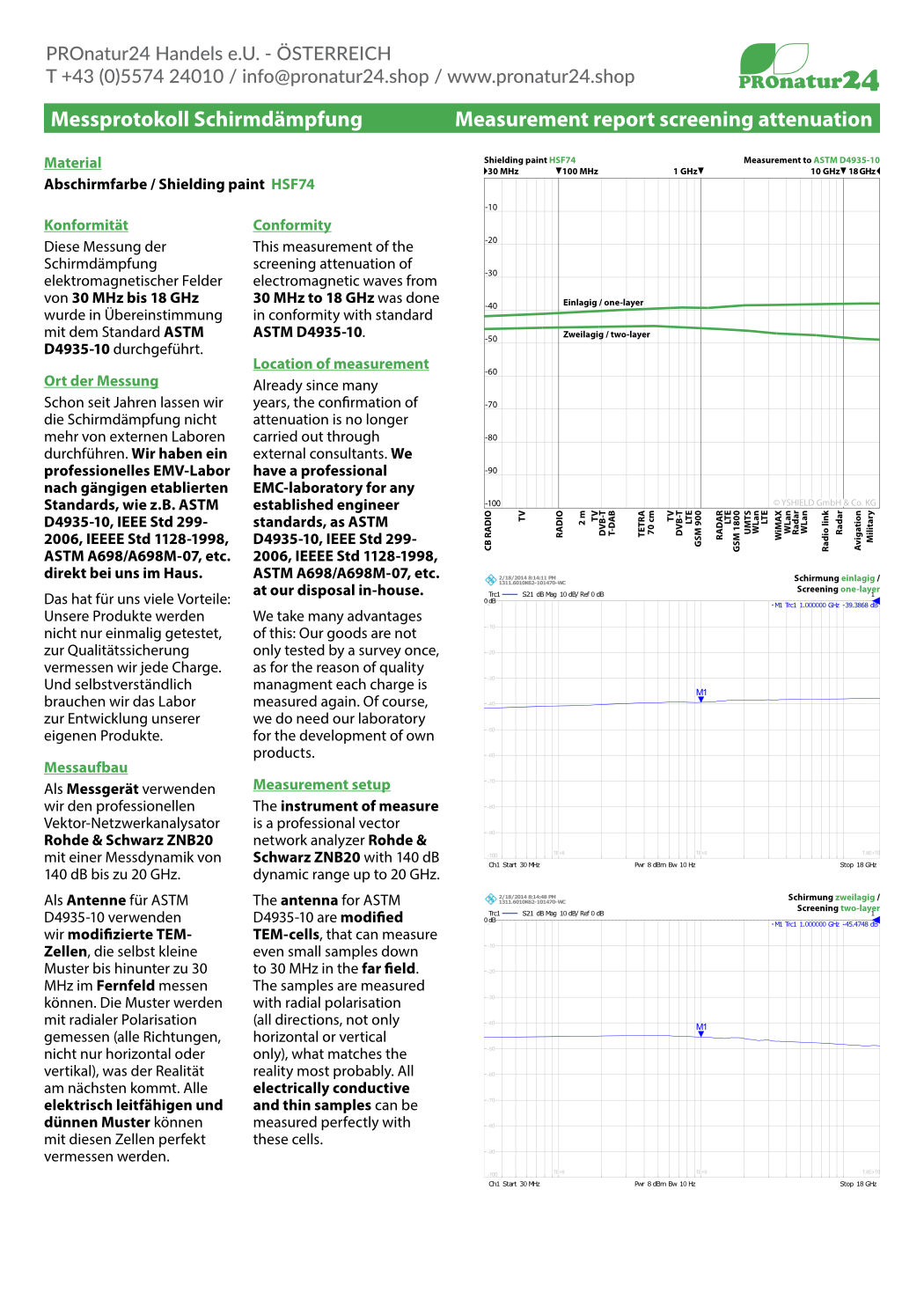

HF attenuation, one layer: up to 39 dB

HF attenuation, two layers: up to 45 dB

SALE OF REMAINING STOCK: No return/revocation possible!

Delivery time: approx. 3-5 business days

Just like for the HSF64, the environment is paramount for the YSHIELD HSF74 shieldingShielding is the protection from the effects of external fault zones and environmental influences (on a person's health most of the time). More paint, but the focus is also on people who are allergic to preservatives. The base of a shielding paint is usually a pure acrylate, but for the HSF64, it was changed to pure silicate paint with a minimal amount of ingredients and no preservatives. The shielding paint was developed with a potassium water glass base.

With the HSF74, YSHIELD could increase the screening attenuation to 45 dB, compared to the 44 dB that could be achieved with the HSF54 shielding paint, this means twice the shielding effectiveness. An increase from 44 dB to 45 dB is a substantial increase of the shielding effectiveness.

As a pure silicate paint, the HSF74 shielding paint has limited moisture resistance and, therefore, is only suited to indoor use. HSF74 is highly alkaline with a pH value of 12 because of the use of potassium water glass. As a result, the HSF74 shielding paint must be used with protective equipment. HSF74 is breathable, solvent-free, neutral odor, and low-emission.

The HSF74 shielding paint by YSHIELD is best suited to the effective attenuation of stress caused by electrosmogElectrosmog is a colloquial term for all emissions from electric, magnetic, and electromagnetic fields. More from mobile radiation and electric alternating fields. Radio pollution from mobile phones, mobile Internet, WLAN, DECT, GSM, LTE, and many more is attenuated by up to 45 dB, which is an effectiveness of 99.997%. Electric fields from the power supply (alternating current) are grounded very effectively and can be attenuated by 100% (same as PRO54, HSF54 and HSF64).

We always strongly recommend two-coated protection, which means painting twice. The HSF74 shielding paint must be grounded!

Generally speaking, the yield of a shielding paint is necessary depending on the surface. The more the surface “sucks”, ie. is coloured, the more shielding paint is required. We recommend conducting small tests to see how quickly the paint “enters”. We highly recommend using our primer because that will prevent an excessively-high usage of HSF74 shielding paint. The “average” yield is based on a “non-sucking” surface.

You need to mix the HSF74 shielding paint extensively before applying it. The heavier ingredients will have sunk from storage and transport, and this must be corrected. With the stirrer that we have developed ourselves it is possible to effortlessly and effectively re-mix and re-apply the HSF74 shielding paint. Simply insert it into a standard electric drill and mix for around 5 minutes per container. There should be no more solid remains of the solid ingredients at the bottom of the container – these would make the shielding less effective because they wouldn’t be put on the wall, but they’d remain in the paint bucket.

Stirrer for shielding paints GK5 primer

All electrically conductive surfaces must be grounded by a qualified electrician in accordance to the DIN/VDE regulations. This can be done over the electrical system’s grounding support (ground contact in the socket) or on the grounded heating pipe of the wall heaters (radiator). A protective circuit also needs to be installed in the fuse box. It must be noted that the circuit must be turned off before painting – a 230-volt, 16-amp shock can be deadly! The electrified flush-mounted box must be a centimeter away when painting the wall.

Electrical alternating fields can be grounded, contrary to mobile radiations (high-frequency) which are based on reflection and cannot be grounded as a result. A protection against mobile radiation is also based on reflection whereby the electromagnetic radiation is prevented from entering the room.

The HSF74 shielding paint shields against both emissions by grounding and reflecting electromagnetic radiations.

Self-adhesive conductive grounding tape for shielding paint Conductive carbon fibers as an invisible alternative to the ground tapeATTENTION: SAVE BARE MONEY BY PRIMING!

A pre-treated substrate saves money because less shielding paint is needed. Depending on the surface, up to 20% of the expensive shielding paint can be saved. For untreated fine plaster and coarse plaster, we EXPRESSLY recommend pre-treatment with our GK5 primer before applying the shielding paint. For already painted surfaces using eg. Disperse paint can be dispensed with, since relatively little reduction effect can be achieved.

| Filling quantity | |

|---|---|

| Screening attenuation | up to 45 dB, All given attenuation values apply to 1 GHz. Measurement based on ASTM D4935-10 or IEEE Std 299-2006 or IEEEE Std 1128-1998 or ASTM A698/A698M-07. |

| Application (coverage) | Interior: up to 7,5 m² per liter |

| Reaction to fire | flame-retardant according to DIN 4102-1 (B1) |

| Application | Ceiling, Floor, Indoor wall |

| Field type | HF (high-frequency electromagnetic field), LF (low-frequency electric alternating field) |

| Ecology | Very high |

| Colour | |

| Ingredients | Anti-foaming agents, Carbon black, Cellulose, Emulsifier, No preservatives, Potassium water glass, Water, Graphite |

| VOC content | 0.1 g/l (since 2010, the EU limit for the A/a category is 30 g/L). |

| SD value | 0.02 m |

| pH value | 12 |

| Disposal | Liquid material residues are waste from water-based paints, dried material residues are domestic waste. Do not let it reach the sewer system, water, or soil. |

| Adhesive strength | 1.7 N/mm² |

| Shelf life | 12 months |

| Brand | |

| GTIN | 4260103662727, 4260103662710 |

HSF74 shielding paint. REMAINING STOCK. HF attenuation of up to 45 dB, LF grounding mandatory. Without preservatives. 5G ready!

HSF74 shielding paint. REMAINING STOCK. HF attenuation of up to 45 dB, LF grounding mandatory. Without preservatives. 5G ready!

Shielding accessories

Shielding accessories

Demand switch

Shielding accessories

We use cookies to give you the best online experience. By agreeing, you accept the use of cookies in accordance with our cookie policy. Further surfing in the web shop automatically leads to approval.

When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Control your personal Cookie Services here.

Reviews

There are no reviews yet